The RTRY520B Label Flexo Printing Machine is suitable for roll materials of 45 - 450g/㎡ (paper/film/adhesive label, etc.), integrating high - speed slitting, high - precision printing, and intelligent die - cutting functions.

• Imported Web - guiding System: Achieves high - speed and precise slitting of materials with irregular edges. The combined circular knife, matched with a high - pressure fan for waste discharge, ensures clean and efficient production.

• PLC Touch System: Supports one - key parameter setting and automatically lifts the roller to protect materials when the machine stops. Suitable for label production in multiple fields such as daily chemicals, food, and medicine.

Adopts flexographic printing technology, compatible with environmentally friendly inks. Supports wide - format printing and multi - color precise overprinting, capable of presenting high - quality prints from single - color logos to complex patterns, balancing production efficiency and economy.

1. Imported Variable - frequency Power: The main motor uses frequency - conversion speed regulation, stable and adjustable, suitable for high - speed printing of different materials, ensuring long - term production consistency.

2. Intelligent Tension Control: Full - automatic tension adjustment at unwinding and rewinding parts, with real - time dynamic compensation. Eliminates material stretching/wrinkling, especially suitable for easily deformable thin - film materials.

3. Ultrasonic Precise Web - guiding: Imported web - guiding sensor corrects material deviation in real - time, with an accuracy of ±0.2mm, reducing registration deviation and scrap rate.

4. Ceramic Anilox Roller Technology: Key printing rollers are wear - resistant and corrosion - resistant, with a lifespan 3 times that of ordinary steel rollers. Ensures clear and stable dots for long - term high - speed printing.

5. Flexible Registration Adjustment: The printing unit supports 360° phase adjustment, can separate color groups individually, and allows plate - changing/repair without stopping the machine, improving multi - batch production efficiency.

6. Infrared Ultra - fast Drying: Equipped with a standard dedicated infrared device, optimizing the drying speed (60m/min) for inks.

7. Integrated Die - cutting and Molding: Built - in high - precision die - cutting unit supports various die - cutting methods. Printing - drying - die - cutting - rewinding is completed in one go, eliminating the need for post - processing.

8. Intelligent Shutdown Protection: When stopping, the rollers automatically separate and idle at low speed to prevent ink from drying, reducing cleaning costs and material loss.

| load material | Heavy-duty shaftless hydraulic loading. For unwinding, select 3-6 inch air shafts. |

| start | Servo motor control, constant tension and variable frequency speed regulation. |

| slitting | Imported system correction, circular knife slitting and waste edge removal. |

| detection | PLC for length counting. Alarm for remaining material or fixed length shutdown. |

|

rewinding |

Double-station air shaft rewinding, hydraulic automatic unloading. |

|

Descriptions |

Parameters |

|

Model |

RTRY-520B |

|

Printing speed |

60m/min |

|

Printing number |

1+3+4 colors |

|

Max width of paper |

520mm |

|

Max printing width |

510mm |

|

Max unwinding diameter |

1000mm |

|

Max rewinding diameter |

1000mm |

|

Printing length |

175-380mm |

|

Precision of overprint |

±0.1mm |

|

Overall dimension |

4.8(L)×1.6(W)×2.1(H)m |

|

weight |

3800kg |

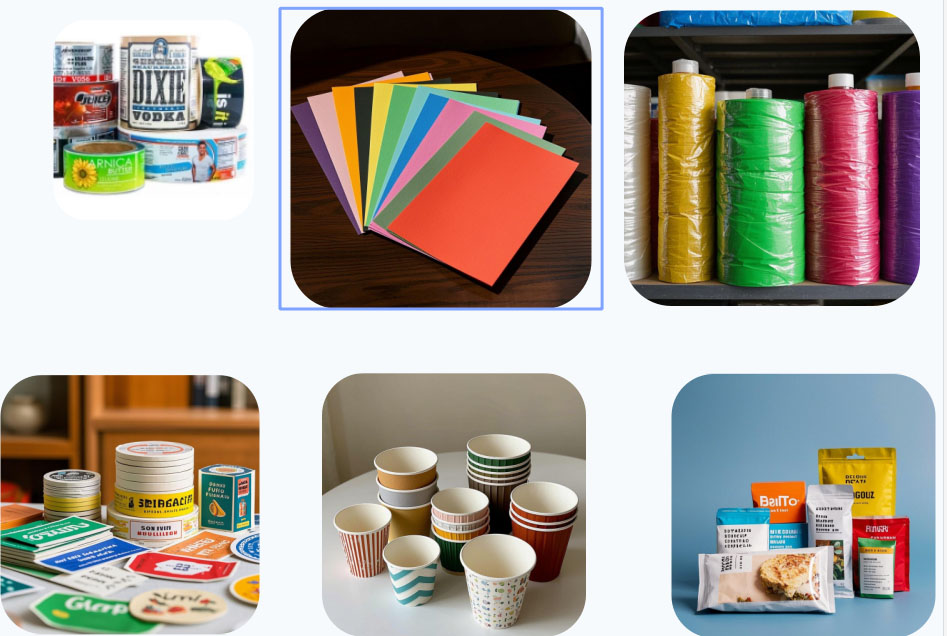

The RTRY520B adhesive label flexographic printing machine can be applied to the printing of various products, such as labels (including various commodity labels, paper self-adhesive labels and wine labels, etc.), paper cups (able to customize paper cups with unique designs for the catering and other industries), packaging bags (used for packaging food, daily necessities, etc.), paper boxes (such as food packaging boxes, medicine packaging boxes, etc.), plastic films, etc.

Do you have a question? Everything you need to know about the product and how it works.

View allLatest Blog Articles

News and Information

Exhibition 2023 labelexpo Asia

What Is a Flexo Printing Machine?

GET A QUOTE